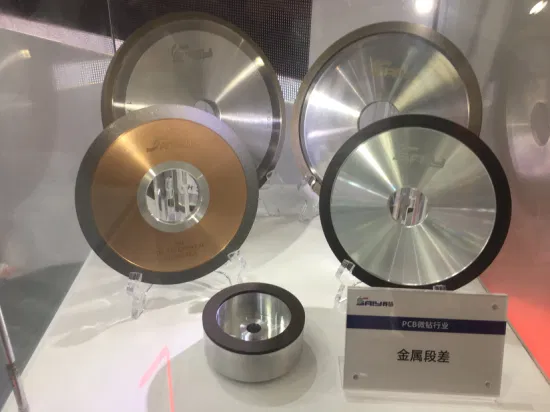

High Precision Diamond Grinding Wheel and Diamond Dresssing Wheel

Application field of diamond roller(1) Auto parts industry: crankshaft, valve body, piston ring, oil needle, oil needle

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | Customized production according to customer needs |

| Tolerance-1 | 2um |

| Tolerance-2 | 0.5 Degree |

| Production Cycle | 35 Days After Drawing Confirmed |

| Transport Package | Wooden Box |

| Specification | Customized production according to customer needs |

| Trademark | jiu li jing gang |

| Origin | China |

| HS Code | 8207901000 |

| Production Capacity | 25000 Pieces/Year |

Product Description

Application field of diamond roller(1) Auto parts industry: crankshaft, valve body, piston ring, oil needle, oil needle body, ball cage universal joint, oil nozzle oil pump, etc.(2) Gear industry: double piece single cone, single piece double cone, gear tooth tip, full tooth surface, etc.(3)Machine tool industry: guide rail, sliding block, ball screw, etc.(4) Bearing industry: ball bearing groove, linear track pair, cone bearing, column bearing groove, textile bearing, etc.(5) The amount of cutting tool industry: caliper, drill, saw blade, milling cutter slotting cutting edge, tap thread, etc.(6) Light industry: refrigerator compressor, bicycle shaft, etc.(7) Hydraulic industry: plunger pump connecting rod, etc.Our advantages(1)High efficiency---Simple operation, high dressing efficiency, long service life, stable quality(2) Stable accuracy---The grinding wheel with complex surface which cannot be finished by other dressing methods can be trimmed, and the surface quality and accuracy are stable(3) Small tolerance---The angular symmetry tolerance of diamond dressing roller is controlled at 0.5 degree, and the minimum tolerance of arc is guaranteed within 2um(4) the machine preparation time is short---The diamond roller greatly reduces the dressing time, improves the production efficiency and reduces the wear degree of mechanical equipment(5) Customize---Provide customized service according to customer requirements and drawingsCustomized information (Buyer fill in)| Part name | |

| Workpiece material | |

| Surface roughness requirement | |

| Grinding wheel specifications | |

| Drawing of diamond grinding wheelor drawing of diamond roller | |

| Current pain point |

Some successful cases photos